Unveiling the Magic Behind Augumenta’s AR accuracy: Camera Calibration in Smartglasses

Introducing camera calibration and its importance in high-accuracy augmented reality

How hundreds of millions can be saved every year by large logistics operations thanks to smartglasses and SmartMarkers.

In a previous article we explained why QR-codes are a very poor choice for smartglasses users. This week we would like to show how much money can be saved by large logistics operations by switching to industrial-grade 2D markers that were designed for smartglasses, like our SmartMarkers.

If we have to talk about large operations we might as well go big. Go big or go bust right? So let’s have a look at… Amazon.

Classic barcode scanning requires picking a reader, hand movements, aiming, alignment, etc… All these manipulations require precious time and energy. Head-mounted devices like smartglasses bring two huge advantages over these classic scanner solutions:

Smartglasses combined proper industrial-grade 2D barcodes like our SmartMarkers will therefor be much, much faster: just look at the item and its marker will be scanned instantly! We’re going to be a little pessimistic and say that this improvement will only make scanning 0.5 second faster per operation (I would personally think it’s more like 1 to 2 seconds, but IANALP – I Am Not A Logistics Professional).

The target picking time at Amazon is 7 to 10 seconds per item. One second is thus 5 to 7% faster. A typical Amazon picker is paid around 18$/hour. If each picker works 8 hours per day, 250 days per year, this represents 2000 hours a year, or $36000 per picker (this number does not include overheads, benefits and so on; once again we remain conservative). Amazon has around 1.5 million workers, but this figure includes part-time employees. We’ll suppose that this equates to about 900.000 full-time employees, among which we’ll further suppose that only 250.000 are pickers. It’s probably more, but again we are voting conservative 😉 The total annual cost of this workforce amounts to 250.000 x $36.000 = $9 billion. If we can make the workers just 7% faster and thus save 7% of that amount, amazon could save $630M per year by using smartglasses and proper 2D barcodes.

Importantly, the life of the workers would also improve as they would have less manipulations to do and would globally work much more seamlessly. We can also hope that the productivity gains would be shared with the workforce, allowing them to have more frequent pauses for example. This helps retaining employees, improves the overall atmosphere and life of the workers and in turn helps concentration and reduce errors.

Of course smartglasses have a cost. Assuming that each worker’s glasses will cost $300/year (purchase, maintenance,…) and that the software will cost $10/month, the total cost per year per worker is 300 + 120 = $420. Which for 250.000 workers amounts to $105M.

Thus the net savings for Amazon when using our SmartMarkers with smartglasses would be in the order of $525M/year. Yes, that is over 500 million dollars. Per year. And this only touches pickers: many other roles can benefit from this technology. Van drivers covering the last miles, for example, could also get driving and delivery instructions with smartglasses.

Hey Amazon, time for a chat?

(Warehouse image CC-by-2.0)

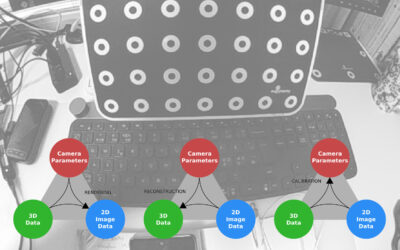

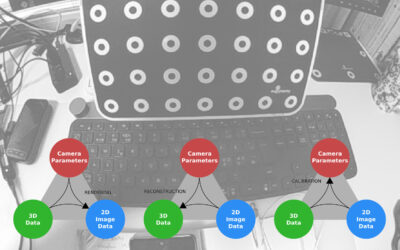

Introducing camera calibration and its importance in high-accuracy augmented reality

The eye box is the secret behind good AR UX. Discover what it is and how to take full advantage of this hidden smartglasses spec

How millions can be saved every year by introducing SmartPanel and smartglasses to reduce airframe weight, shorten idle time and shrink ground crews.

Standard QR codes are poor candidates for professional smartglasses use cases as they were designed for hand-held scanners, not head-mounted cameras. What you can do about it?