Customer Use Cases

Augumenta has served many customers during its 10+ years of operation. Below are a few practical examples of public customer use cases that we can share with you to better illustrate what Augumenta’s solutions can do to improve your operations. Get inspired and get in touch!

(Note that for confidentiality reasons some illustrations below are conceptual only.)

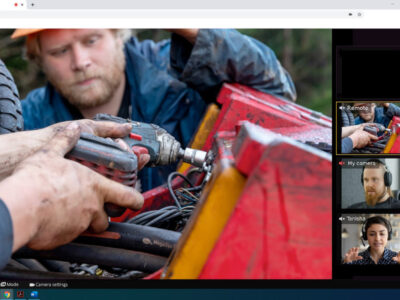

![]() Problem: Forestry and agricultural machines break down in remote places. Waratah is looking for a straightforward way for field workers to contact support.

Problem: Forestry and agricultural machines break down in remote places. Waratah is looking for a straightforward way for field workers to contact support.

Solution: SmartEyes connects experts and field workers with the press of a single button, letting them exchange live video, documents and annotated images. The app can be installed on the phone or smartglasses of any worker.

ROI: Significant reduction in downtime in the field, faster turnaround in repair shops and improved sharing of expert knowledge, all from a single application!

Problem: Kiilto is a large glue and chemicals manufacturer from Finland. During COVID restrictions, new factory processes involving glue products could not be tested in customer’s factories.

Problem: Kiilto is a large glue and chemicals manufacturer from Finland. During COVID restrictions, new factory processes involving glue products could not be tested in customer’s factories.

Solution: Our SmartEyes field kit is sent together with the Kiilto product. The box contains the smartglasses, camera kit and internet modem. It is activated upon arrival by the customer, who can then get live video support from Kiilto’s experts. Kiilto can also monitor within the same system live IoT parameters like glue temperature.

ROI: Continued operations through COVID19 travel restrictions periods and reduced need for in-person customer visits afterwards.

Read more about this use case in our blog article.

Problem: JICA Projects in Africa stalled with Covid as Japanese staff was repatriated. There was an urgent need for a simple and efficient communication system for critical international cooperation projects.

Problem: JICA Projects in Africa stalled with Covid as Japanese staff was repatriated. There was an urgent need for a simple and efficient communication system for critical international cooperation projects.

Our solution: JICA selected Augumenta among 24 contestants to supply trans-continental, hands-free telepresence for medical projects in Zambia and Ghana. Using SmartEyes and our partner Iristick’s smartglasses, projects were able to continue their teaching and training operations.

ROI: Continued operations through travel restrictions periods. Post-COVID, SmartEyes can reduce JICA’s travel needs and budget significantly.

Read more about this use case in our blog article.

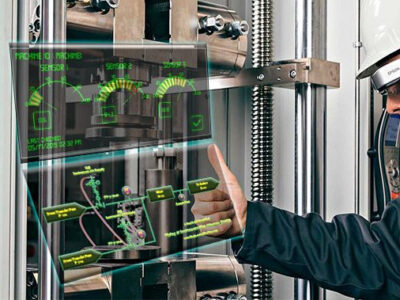

![]() Problem: CNC machine control panels are fragile and hard to maintain or upgrade. What new technology could replace them?

Problem: CNC machine control panels are fragile and hard to maintain or upgrade. What new technology could replace them?

Our solution: SmartPanel was designed for Siemens using custom computer vision algorithms. The fully AR interface is impervious to the liquids, dust and metal shavings found in workshops. It can also be tailored to each worker’s role (junior, supervisor…)

ROI: The fully software-defined panel has potential to drastically reduce maintenance and upgrade costs but is still in the testing phase. Applications like IoT panels and the advantage of role-based UIs are also being envisioned.

Read more about this use case in our blog article.

Problem: Elevator shafts and machine rooms are dangerous environments. The manufacturer wants to be sure that the operator is in front of the control panel when some critical procedures are performed. No tablet allowed, and operation must be traceable.

Our solution: SmartPanel not only provides the interaction but can also position the user, fitting the safety request perfectly With no active parts, it is also ideally suited for the hard-to-reach, rarely used environments that are elevator shafts and machine rooms.

ROI: Strong safety improvements with the added bonus of lower TCO. A better control of the qualified maintenance operations workforce can also be achieved as only selected operators are equipped with SmartPanel applications and can access critical functions.

Problem: Parts production tests are inconsistent due to human errors. A connected solution to measure tool rotation is required.

Our solution: SmartMarkers are used with smartglasses to automatically measure rotation accurately. Worker interaction is minimized to avoid errors. Measurement and worker performance are logged.

ROI: Dramatic improvement of quality assurance on the production lines. Identification of poor performing staff helps target training efficiently. Identifying the steps that are more complex and take more time to learn or perform also helps designing better procedures. Best of all, the personnel have welcomed the solution as they can see it directly helps them in their everyday tests.

![]() Problem: For safety reasons in case of a chemical hazard, the last known location of field workers must be readily available, both indoors and outdoors.

Problem: For safety reasons in case of a chemical hazard, the last known location of field workers must be readily available, both indoors and outdoors.

Our solution: Helmet-mounted smartglasses detect SmartMarkers seamlessly at each door and other key locations, providing live updates of the worker’s indoor location to safety operators. Combined with GPS for outdoors operation.

ROI: Critical improvement of the safety and awareness of the workforce on the entire site. Future tracking of the workers’ performance is possible for further enhancements of training procedures.

Read more about this use case in our blog article.

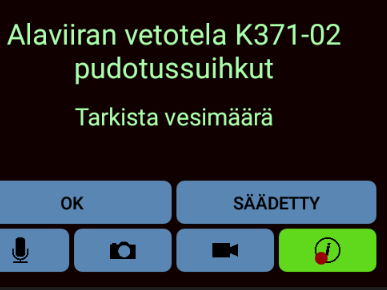

Problem: Machine parameters are not readily visible to maintenance crews in a large HVAC installation. QR codes don’t work: too dark, too slow, and not detected at larger distances. A seamless information system is needed.

Problem: Machine parameters are not readily visible to maintenance crews in a large HVAC installation. QR codes don’t work: too dark, too slow, and not detected at larger distances. A seamless information system is needed.

Our solution: Hands-free smartglasses let workers know how machines are operating, showing the right IoT data seamlessly as soon as a marker is detected. SmartMarkers are fast and reliable even in low-light, a requirement for this facility. Combined with SmartEyes so workers can contact support in case of trouble.

ROI: Much faster and more systematic checking rounds in the complex HVAC installations with traceability and history. Worker localization also improves safety.

Read more about this use case in our blog article.

![]() Problem: Workers cannot follow automated factory delivery robots or interact with them.

Problem: Workers cannot follow automated factory delivery robots or interact with them.

Our solution: Smartglasses detect SmartMarkers in real time, all the time, and allow personnel to verify robot and payload status seamlessly. Simple interaction is provided with head tracking, voice control or gestures. SmartPanel is also tested.

ROI: Robot content and other operational information is now accessible in a fully transparent way to all workers, saving time with more efficient planning and routing. Safety is also improved through better awareness and integration of the mobile robots in the workers’ environment.

Read more about this use case in our blog article.

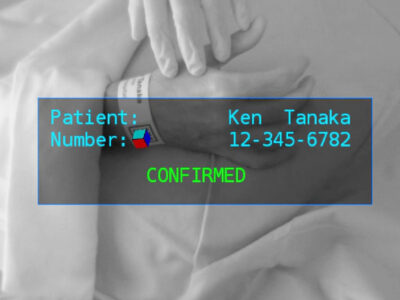

Problem: Patient identification is done by scanning individual bracelets with QR-codes using mobile phones. A faster and hands-free method is sought that can also grow to include step-by-step instructions in the future.

Our solution: Using SmartMarkers with smartglasses resulted in much faster and reliable scanning of patient and medicine tags while keeping the nurses’ hands available at all times.

ROI: Hands-free scanning is a dramatic improvement compared to hand-held solutions like smartphones and tablets. Saves time, reduces required manipulations, improves the medication safety, reduces the nurses’ workload, provides better traceability and can be used also for managing nurses task scheduling. That’s a lot in one app!

Problem: Liquid Controls is a leader in aircraft refueling pumps. They identified an issue in their operations: personnel are not aware of fuel parameters during refueling operations on the tarmac. Hands-free and non-contact is a must due to the dirty product and environment.

Problem: Liquid Controls is a leader in aircraft refueling pumps. They identified an issue in their operations: personnel are not aware of fuel parameters during refueling operations on the tarmac. Hands-free and non-contact is a must due to the dirty product and environment.

Our solution: Hands-free smartglasses connect to refueling trucks and provide live data to workers regarding fuel volume, water content and other parameters.

ROI: Reduced the required refueling staff by 50%.

![]() Problem: Nokia has large automated SMT high-tech assembly lines. Few workers monitor the line, and sometimes miss important alarms. When multiple alarms are triggered, prioritization is also required.

Problem: Nokia has large automated SMT high-tech assembly lines. Few workers monitor the line, and sometimes miss important alarms. When multiple alarms are triggered, prioritization is also required.

Our solution: Augumenta provided the workers with a hands free access to real-time IoT information from the production systems. Both smartglasses and smartwatches were used.

ROI: Significant reduction in downtime of the SMT line by providing timely and informed response from workers when alarms are triggered. Personnel stress also reduced down a few notches now that they are sure not to miss any critical situation.

Problem: The customer’s mills require regular checks and maintenance. Workers are still using paper checklists for the daily inspections, which requires re-logging in digital format afterwards. A fully digital, hands-free and multimedia solution is needed.

Our solution: Augumenta created an application for smartglasses that lets workers go through checklists step by step. Pictures or videos can be attached to each step to document potential issues.

ROI: Completely eliminated the time wasted copying preventive maintenance data from paper to computer and streamlined the entire inspection process. Used to produce training content and passing critical knowledge to next shifts.

Problem: Improve in-company maintenance training by creating a knowledge base of annotated videos, suitable for AI processing.

Our solution: Augumenta combined forces with an AI specialist to provide this solution. Our smartglasses application used gestures to interact. Recordings are analyzed by AI in the cloud and marked for later context searching. Plans to use our gestures algorithms for 3D sensors (ToF) were also made but ultimately not implemented.

ROI: Significantly reduces the content management and retrieval efforts of video recordings.

Problem: Betz Chrom was still using paper checklists to prepare large chrome-plating industrial processes. A modern hands-free solution with smartglasses was required. The documentation already existed in PDF, so using that format was also a requirement to avoid unnecessary costs.

Problem: Betz Chrom was still using paper checklists to prepare large chrome-plating industrial processes. A modern hands-free solution with smartglasses was required. The documentation already existed in PDF, so using that format was also a requirement to avoid unnecessary costs.

Our solution: Augumenta designed a PDF viewer that the worker can easily interact with using gestures to flip between pages of the document.

ROI: Reduces errors from junior workers while providing them with hands-free instructions. Reduces the effort to create and update documentation.

Problem: ABB wants to improve their logistics operations. Assembly can require many parts that have to be picked manually, leading to picking errors and delays. A more fool-proof approach is required.

Problem: ABB wants to improve their logistics operations. Assembly can require many parts that have to be picked manually, leading to picking errors and delays. A more fool-proof approach is required.

Our solution: We designed a SmartGuide solution that shows the location of items to be picked for each task as well as the walking path to the pickup location in the warehouse.

ROI: Important reduction in walking distances thanks to the planning of the optimal picking route. Worker performance tracking for better optimization of SOPs.

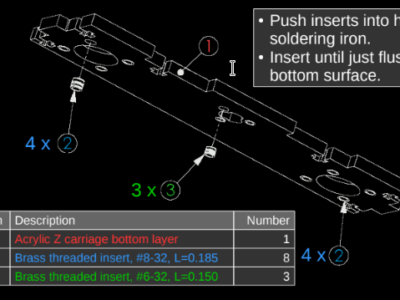

![]() Problem: FX-Media is knowledgeable in AR but lacked proper smartglasses interaction method for their PoC application.

Problem: FX-Media is knowledgeable in AR but lacked proper smartglasses interaction method for their PoC application.

Our solution: FX-Media used Augumenta’s SDK for hand gesture recognition to control the application. An overlay was shown when the worker’s open palm was detected, and scrolling was achieved with the thumbs-up and thumbs-down gestures.

ROI: Much better access to information saves the workers’ and company’s time.

Read more about this use case in our blog article.