Unveiling the Magic Behind Augumenta’s AR accuracy: Camera Calibration in Smartglasses

Introducing camera calibration and its importance in high-accuracy augmented reality

How millions can be saved every year by introducing SmartPanel and smartglasses to reduce airframe weight, shorten idle time and shrink ground crews.

Weight saving is a critical aspect of every aerospace business. So much so that crews of commercial airlines will be instructed to carefully clean the cabin, not only to make it nice for the next passengers, but also and very importantly because carrying trash means wasting money. A lot of money. How much? Every extra 100kg on an airplane requires 5 tons of fuel per year! And we didn’t even talk about ecology and global warming yet…

You may wonder how an AR company like Augumenta can help save the airlines and the planet. Well it’s rather simple 🙂 AR user interface are virtual and thus weight nothing. Our SmartPanel can thus replace heavy and maintenance intensive control panels with a solution that only requires a lick of paint and is basically maintenance free. So how much can be saved? For our calculations we will use the official Airbus document Getting To Grips With Fuel Economy which among others contains the 5 tons of fuel/year figure mentioned above.

Augumenta has worked in the past on an aircraft refueling use case in collaboration with Liquid Controls, so let’s take this as an example. During refueling, the ground crews have access to a control panel located on the fuselage of the aircraft, behind a trapdoor. This is a large and heavy piece of equipment that also requires significant cabling within the aircraft (the image above is an example of such heavy refueling control panel on a large military cargo plane).

It is hard to find numbers on the weight of the control panel so we will guestimate the total at 75kg, including the panel itself, the cabling, the extra mechanicals required for the doors, etc… As we mentioned earlier, 5 extra tons of fuel per year can be saved per extra 100kg on the aircraft (Airbus document, paragraph 4.2.3, page 13). Hence, replacing the refueling control panel with our weightless SmartPanel will save about 75kg / 100kg * 5 tons = 3.75 tons of fuel per year and per aircraft.

Next we have to estimate the cost savings for the entire fleet of the airline. Ryanair is well known for its drastic cost cutting measures which allowed them to revolutionize the airline market. So let’s use them as an example of company who would probably be very keen on saving more money. As of today their fleet is 565 airplanes strong, and thus the total annual fuel saving per year for Ryanair would be over 2100 tons.

On top of that, using smartglasses to monitor the refueling process like we did for Liquid Controls can save 2 minutes of idle ground time, further reducing the APU fuel required by 4 tons per aircraft per year (paragraph 4.6, page 22 of the Airbus document). This brings the savings to 4200 tons/year. With the current price of jet fuel around 750 euros per ton, Ryanair would save over 3 million € per year on fuel costs alone.

In addition to fuel savings from our SmartPanel, using smartglasses with SmartGuide lets a single worker perform the refueling and its monitoring operations where normally two persons would have been required. With a 226 airports served and an average ground crew salary of 42000€ / year we can see that using smartglasses can lead to another 10 million euros saved per year even if we limit ourselves to one or two fuel trucks per airport and even if we don’t take overheads into account. Overall, the savings thanks to SmartPanel and smartglasses for refueling operations are now over 13 million € per year for our friend Ryanair. Not bad!

The numbers can get even higher once we take into account the reduced cost of the air frame, the reduced maintenance requirements, the higher reliability (no hole in fuselage required, no active parts…), the reduced idle time on the tarmac and the higher availability of the airplane.

And of course this can be applied to other control panels in the cabin, the galley and the cargo area to bring even more savings.

For cheaper and greener flights, go Augumenta!

Oh and… Hey Ryanair and Airbus, time for a chat? 🙂

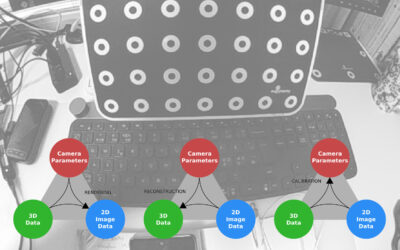

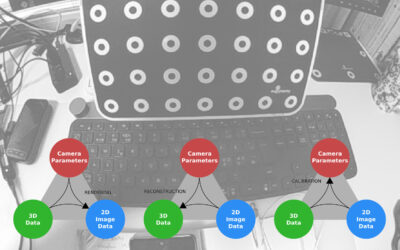

Introducing camera calibration and its importance in high-accuracy augmented reality

The eye box is the secret behind good AR UX. Discover what it is and how to take full advantage of this hidden smartglasses spec

How hundreds of millions can be saved every year by large logistics operations thanks to smartglasses and SmartMarkers.

Standard QR codes are poor candidates for professional smartglasses use cases as they were designed for hand-held scanners, not head-mounted cameras. What you can do about it?