Unveiling the Magic Behind Augumenta’s AR accuracy: Camera Calibration in Smartglasses

Introducing camera calibration and its importance in high-accuracy augmented reality

We aim at making our interactive AR apps as intuitive and easy to use as possible, and we´re on the right track according to the usability test.

Type the keywords in your search engine in an effort to learn more about AR for industry 4.0, and there’s a flood of information available; definitions, predictions, solutions, what to do and what not when considering an enterprise AR solution. Finding the relevant data amongst the multitude of sources, it’s not that simple.

Well, we’re trying to put in our bit and share with you all the best information we have on Augmented Reality and solutions for smart industries. Aiming at picking the relevant and not adding to your burden, we’ll start with sharing some real results on usability of our software.

Augumenta software was chosen to be a part of an AR concept evaluated within MaxiMMI, a Siemens lead project addressing the problematic of increasing complexity of machine operating systems and growing heterogeneity of users working with those systems. Simply put, the goal of the project was to study and develop new user-centric machine control concepts. The results we refer to here were presented to the audience in EMO Hannover 2017 expo by Siemens.

Traditional control panels are complicated and located in fixed places. Operators have to walk back and forth, between a machine and its control. They do not have the relevant data easily available via the complicated control panel. Or more importantly, do not have the machine and the data in sight at the same time to make adjustments to the process quick and easy. A mobile device has to be carried around and does not leave your hands free or might be lying in the way of the operator. These were some of the pain points that the AR concept was set to address in the study.

The chosen approach was to display important data to a user via smartglasses and enable on-demand operation and input via a control panel that appears when the palm of the user is detected. We provided the software and tools, and the guys at Siemens Digital Factory Division built the application for the study.

The app was then evaluated with real users operating CNC machines. An operator was able to see both the process and process data at the same time. With smartglasses the operators’ hands were free so they could choose to interact with the machines directly or choose to adjust the process via the simple virtual control panel displayed onto one hand and operated with the other. They could do this from wherever they were standing, and, well, your hands naturally come with you and hardly ever lie in the way.

The software in the study got remarkably good grades. There were nine factors presented in the evaluation that directly link to Augumenta software, such as stability of tracking and display, use of buttons, reaction time and ease of learning – in all of them the grades were on the top side of the evaluation axis. For example, the stability of hand detection and tracking got highest marks. The stability of display was close behind. And we are very pleased to say: learning to use the solution was considered easy.

We aim at making our interactive AR apps as intuitive and easy to use as possible, with this feedback we hope we’re on the right track.

To sum up, Siemens Digital Factory Division has adopted and is currently using our SmartPanel software. We have received some very nice feedback also on its usability.

Well, no further ado. Have a great start for the year and let us know how we can help you with your AR projects – you know, starting a pilot with us is real easy.

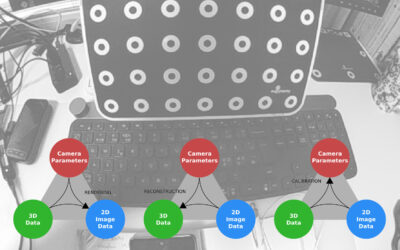

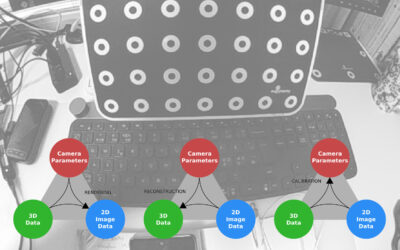

Introducing camera calibration and its importance in high-accuracy augmented reality

The eye box is the secret behind good AR UX. Discover what it is and how to take full advantage of this hidden smartglasses spec

How hundreds of millions can be saved every year by large logistics operations thanks to smartglasses and SmartMarkers.

How millions can be saved every year by introducing SmartPanel and smartglasses to reduce airframe weight, shorten idle time and shrink ground crews.