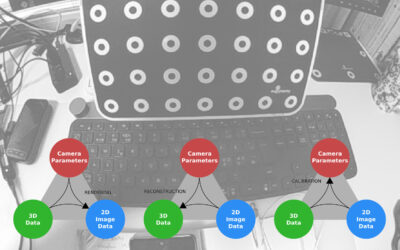

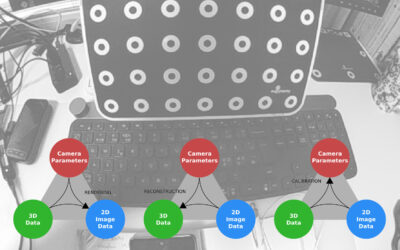

Unveiling the Magic Behind Augumenta’s AR accuracy: Camera Calibration in Smartglasses

Introducing camera calibration and its importance in high-accuracy augmented reality

Industry 4.0. Where should we start? What is the data we have and need, and what to do with it? What is the key value of the change for your company and your customers?

Industry 4.0, smart industry, or digital factory, these terms all refer to several major technology innovations that together are expected to cause a major shift in the landscape of manufacturing industry. Technologies like advanced robotics, AI, sophisticated sensors, cloud computing and big data analytics all exist today but integrated they would create a fully connected and flexible software system that runs the physical manufacturing.

If we consider this the ideal world of manufacturing we’re pursuing, in most cases we are not even close yet. For any company bridging the physical and virtual worlds is a huge challenge to take on as a whole. Where should we start? Do we just go for digitization for digitization’s sake; what is the data we have and need, and what to do with it? What is the key value of the change for your company and your customers? Most of us are not equipped with enough information to answer that all in one go. Luckily you can start small!

Let’s choose here a simple example case of adopting one of the key technologies of Industry 4.0 – Augmented Reality. Enterprise AR is starting to be a serious success factor to any industrial enterprise; it has clear use cases and proven ROI. It is a technology with proven track record of measurable results in reducing errors and saving time.

Let’s go further and take a modern production line in a manufacturing company and assume the bottom line here is to run that line with no bottlenecks and as close to zero downtime as possible. Downtime is enormously expensive to any manufacturing business. To give a glimpse of the magnitude: for UK manufacturers alone downtime costs £180bn a year according to a study published last autumn and cited for example by the Engineer.

In large production facilities the space and number of devices may be huge and the operators scarce. An operator may be able to see notifications of possible problems from a dashboard in a fixed location or from control room screens. But on a high-volume production line small issues will cumulate into large ones in a blink of an eye if an alert on a dashboard goes unnoticed or was seen too late. In a low-volume production line the errors may not be very frequent but a single error can be drastically expensive.

AR makes the monitoring and reaction to any problem faster and easier. The work of operators becomes a lot more flexible than with traditional equipment. With a simple AR app on smartglasses we can display the exact piece of data needed at the right time and in the right context. We can allow operators to interact with the faulty machine right from where they are standing. From the point of view of a worker on shop floor, AR apps are easy to learn, easy to use tools.

Starting with a very low-entry use case, Augmented Reality can be deployed to warn the operators of any problems the production line might be facing. Know when the vibration levels of a machine start to rise and fix it ahead before they cause serious damage. Avoid losing an expensive set of components when a reflow oven goes haywire and tries to grill them to ashes. Displaying simple information bursts using monocular smartglasses, and allowing the operators to interact with a machine quickly and efficiently helps prevent those so expensive production line downtimes. No advanced mathematics are needed to calculate the benefits.

This is a simplified example to show that AR is a tangible and effective tool in the manufacturing industry already now. The further towards the ideal case we go in bridging the physical and the virtual, the more quality data is available and the more elaborate use cases exist for Augmented Reality. Smart AR glasses and apps by industrial AR solution providers like Augumenta enable new ways to monitor and control machines and get a hold of that information IoT devices provide. From low-entry to more advanced systems, we have the pieces ready for you to use today.

So, what are the questions you should ask if you have decided Industry 4.0 and AR is the way to go? Based on our experience from a multitude of pilot projects we have established these key points one should focus on. You’re welcome to take a look at: checklist for industrial augmented reality pilots.

The value of starting the project now is in gaining the knowledge that you will need to make the digital transformation and with tools that already now can save you time and money. Collecting the data from these smaller projects allows you to see, which solutions work, which don’t, what directions you should take. You’ll have the tools, knowledge and skills to productize these technologies in larger scale. If you wait too much for the perfect techs to appear and try go for it all in one strike, you may never get to the end of it. Taking smaller iterations at a time makes it easier to manage the costs, evaluate the benefits, and introduce the changes in your organisation.

So, get a good partner for the journey and start today!

Introducing camera calibration and its importance in high-accuracy augmented reality

The eye box is the secret behind good AR UX. Discover what it is and how to take full advantage of this hidden smartglasses spec

How hundreds of millions can be saved every year by large logistics operations thanks to smartglasses and SmartMarkers.

How millions can be saved every year by introducing SmartPanel and smartglasses to reduce airframe weight, shorten idle time and shrink ground crews.